Application:

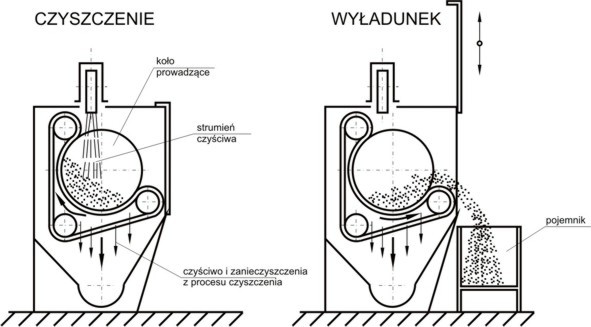

The machines are designed to clean small and medium-size iron and steel castings of dimensions and weight within the limits indicated in the technical specifications below. The cleaning process is effected by shot ejected by a projecting rotor in a closed working chamber on a perforated rubber belt stretched on drums. Castings are removed from the machine by activating reverse gear of the belt. Castings are loaded into the machine by loading hoists type WOWT-120C and WOWT-400A which are ordered separately.

Advantages:

Owing to partially automatic working cycle the fettling operation is simple and safe. One worker is enough to operate the machine.

Technical specifications:

| Unit | OWT-120C | OWT-400A | |

|---|---|---|---|

| Loading volume of chamber |

m3 |

0,12 |

0,35 |

| Acceptable load weight |

kg |

250 |

400 |

| Dimensions of castings | |||

| - min |

mm |

25x25x25 |

25x25x25 |

| - max |

mm |

300x300x300 |

400x400x400 |

| Max. unit weight of castings |

kg |

10 |

40 |

| Approximate shot blasting time of a load of: | |||

| - iron castings |

min |

3 - 5 |

3 - 6 |

| - steel castings | min | 4 - 10 | 6 - 12 |

| Projecting rotor capacity | kg/min | 100 | 150 |

| Recommended shot granulation | mm | 0,5 - 2,5 | 0,5 - 2,5 |

| Compressed air consumption per 8h operation | m3 | 0,01 | 0,01 |

| Working pressure | MPa | 0,4 - 0,6 | 0,4 - 0,6 |

| Total installed power | kW | 9,6 | 14,7 |

| Required capacity of dust extraction system | m3/s | 0,9 | 1,66 |

| Required vacuum at connection pipe |

Pa | 500 | 500 |